I believe not many people will care about the RV wall panels when buying an RV. Most people will care about the configuration and whether the bed is big enough, but very few people will pay attention to the wall panels. As a travel and living tool, the quality of the wall panels determines its stability and durability.

The structure of RV wall panels:

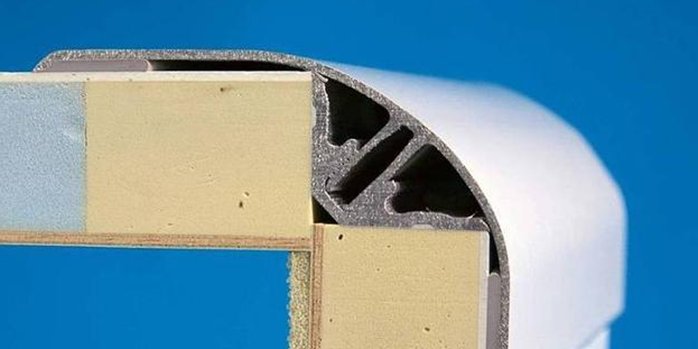

Wall panels play a vital role in supporting the structure of RVs. The wall panels of the car body are generally made of aluminium plates and fibreglass. Almost all wall panels are sandwich composite structures. The outermost one is fibreglass, and the middle layer is a sandwich material with insulation, thermal insulation, waterproofing, and other functions. It is called a sandwich panel. The wall panels of RVs all have frames, just like when we build a house. The wall panels play a supporting and load-bearing role.

RV sandwich materials:

Mainly EPS expanded polystyrene, XPS polystyrene, PU polyurethane, PE polyethene, FEF flexible foam material, PP plastic honeycomb core, etc.

1. EPS Expanded Polystyrene

The skeleton inside the composite structure is a wooden frame filled with EPS-foamed polystyrene, but many manufacturers have abandoned this EPS-plus wood manufacturing process because it has serious defects. Rainwater penetrates the RV through the edges of the roof and windows. The EPS foam in the interlayer will easily rot as soon as it touches water, causing the deformation of the wood. In this way, the interlayer in the wall panel loses its function, and finally, the wall panel loses its original load-bearing capacity, and the subsequent maintenance and repair costs are very high.

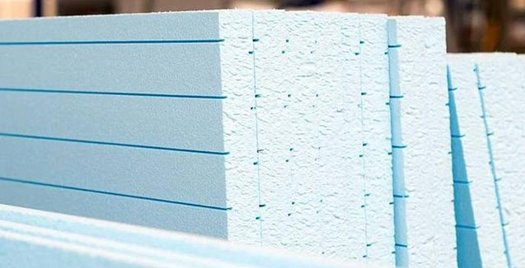

2. XPS Polystyrene

XPS polystyrene is a good insulating material in RV wall panels. It is more waterproof and heat-insulating. It does not absorb water and has a closed-cell structure. It has a smoother and more uniform surface. It is usually blue, green and pink. Because it is very pressure-resistant and hard, it does not require too many reinforcements during installation. It is also heavier than EPS. Due to the high strength of the XPS board itself, the board is brittle and not easy to bend. The stress on the board is stress concentration, which can easily damage and crack the board.

3. PU Polyurethane

RV wall panels are also made of PU polyurethane. It is not used alone but sealed in the wall panel sandwich with other materials. At the joints of the panels, because the highly compressed PU polyurethane is very stable and not easy to rot, it is used to fix screws, roofs, floors, and wall joints. However, this material also has some disadvantages, such as strong brittleness, easy ageing and cracking, and flammability.