4. PE Polyethylene

PE polyethene is a very soft material for wall panels and is very easy to process. Although it is heavy and thin, it has a very good sound insulation effect and is slightly more expensive. Like XPS, it does not absorb water. Many self-modified B-type camping RVs like to use it for insulation.

5. FEF Flexible Foam

FEF flexible foam is a relatively new insulation material, and it is also gradually being used to modify RV wall panels. High-end campers produced in batches like to use it to reduce costs and improve quality. It has high flexibility, the best insulation performance, and is very lightweight. It is not only non-absorbent but also has a good noise-reduction function. It can also prevent the growth of bacteria and mold in the interlayer. It is a material with excellent performance.

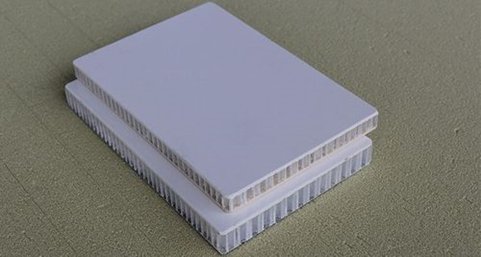

6. PP plastic honeycomb core

PP plastic honeycomb core is a new type of insulation material with a very good strength-to-weight ratio. Honeycomb panels are a bionic structure. With the skins on both sides of the wall panels, an I-beam structure can be formed. It has high strength and the panels have good insulation properties. PP plastic does not absorb water, is resistant to rainwater corrosion, and does not breed bacteria. In addition, it also has the properties of sound insulation, and heat insulation, and is a good choice for lightweight and high-strength car body panels.

Qingdao Achieving Plastic Honeycomb Panel has a production history of more than 20 years. It has now achieved market-oriented mass production with a short production cycle, fast delivery, high quality, and low cost, and can be customized according to specific needs. It can not only be used for RV modification, but also widely used in transportation fields such as interior decorative panels, luggage skins, partitions, decks, etc. for transportation tools such as cars, trains, and aeroplanes. In the field of architectural decoration, such as decorative materials for building exterior walls, partitions, ceilings, closets, etc., it can play the role of heat preservation, sound insulation, and waterproofing. In refrigerated transportation, using insulation panels for refrigerated boxes and refrigerated trucks can effectively maintain the stability and thermal insulation performance of cold air. As well as shipbuilding, medical equipment, furniture manufacturing and other fields.

Each type of insulation material used in RV wall panels has different properties. From the current market perspective, some traditional processes, such as wood and EPS foam, have gradually been eliminated and slowly replaced by new processes and materials, such as plastic honeycomb panels.