Sandwich materials are designed to make composite materials lighter! So, how many kinds of sandwich core materials? And what are the characteristics of each sandwich core material? After reading this article, I believe you will have a better understanding of the core material.

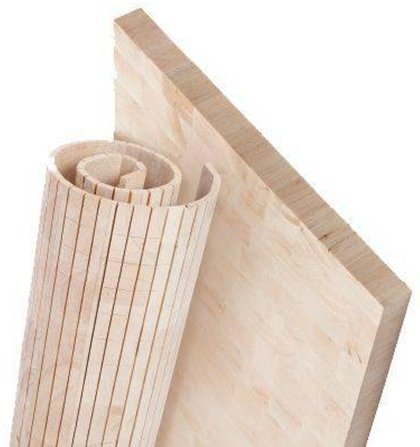

Ⅰ. Balsa wood

Product Features:

•Extremely high strength and hardness (weight ratio)

•Small specific heat and less affected by temperature changes

•Good fire resistance

•Excellent heat resistance and sound insulation properties

•Highly resistant to chemicals used in the composite industry, such as styrene

•Good combination of resins and adhesives

•Suitable for different composite production processes, such as moulding, vacuum bagging, hand lay-up, etc.

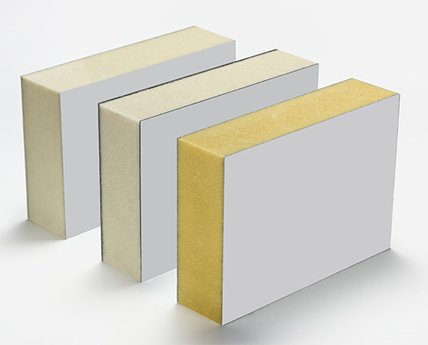

II.PVC foam board

An alloy foam material based on vinyl polymers and polymerized through an aromatic amide network. Customarily called cross-linked PVC foam core material, it is an ideal core material for composite sandwich structures. This product has excellent comprehensive mechanical properties, stable chemical properties, and the highest cost performance. It has been widely used in wind power, watercraft and other fields.

Performance characteristics

•Density range 40~250kg/m3

•Excellent specific stiffness and specific strength

•Good fatigue resistance and impact resistance

•heat insulation

•Good flame retardancy

•Low water absorption, not susceptible to moisture and mildew

•Isotropic

•Good dimensional stability and processability

•Process temperature -240~100℃, long-term use temperature -240℃~80℃

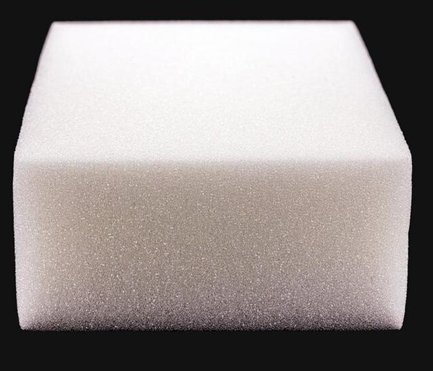

III.PU polyurethane foam board

Polyurethane rigid foam is a polymer made of isocyanate and polyether as the main raw materials. It is mixed with special equipment and foamed on-site through high-pressure spraying with the help of various additives such as foaming agents, catalysts, and flame retardants. things. There are two types of polyurethane foam: soft foam and hard foam. Soft foam has an open-cell structure, while hard foam has a closed-cell structure; soft foam is divided into two types: crusted and non-crusted.

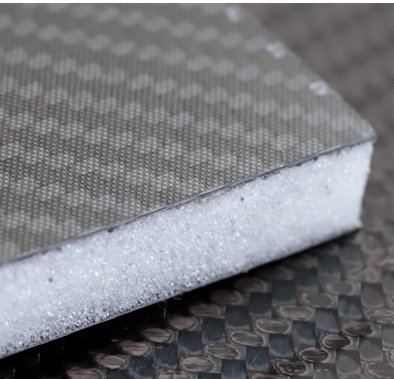

IV.PET foam board

Product features and typical applications

•High-tech, high-temperature sandwich structure applications

•Excellent chemical resistance at room temperature - resistant to solutions, hydrocarbons, weak acids, etc.

•Good mechanical properties - high shear strength and high compressive strength

•Can withstand resin curing exothermic temperatures up to 180°C in a short time

•Recyclable and reusable

•Extremely low smoke emissions

•Excellent FST (fire, smoke, and poison) performance

Polymethacrylimide (PMI) foam is a high-performance, high-quality structural foam material. Used as the core material of high-performance composite materials, it can simplify the process, shorten the process, and solve the problems faced by honeycomb core materials such as coarse pores and easy It solves the problems of moisture absorption and easy debonding, and solves the problems of low specific strength, low specific modulus and low heat resistance of general foam core materials.

The performance advantages of PMI foam are high mechanical properties: high specific strength and high specific modulus. Its tensile, compression, bending, shear and other strength and modulus are far superior to other foams such as PVC, PU, PET and so on. Or balsa wood core and isotropic, which can increase strength, improve rigidity and reduce weight.

PMI is mainly used in the aerospace field, such as the fairing and middle section of launch vehicles. Because of its excellent performance, it can also be used in the rear pressure frame of large passenger aircraft.

The process conditions of PMI rigid foam can reach 0.3MPa, 180℃; after heat treatment, it can even reach 0.7MPa, 180℃.

Therefore, this product is very suitable for autoclave, moulding process and various commonly used resin injection processes.