1. Classification of honeycomb panels on the market

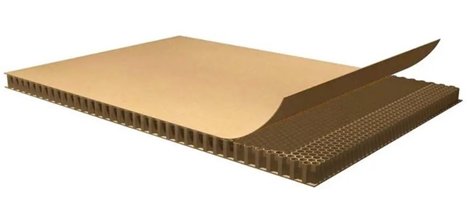

Honeycomb panels are mainly divided into aluminum honeycomb panels, Nomex honeycomb panels and plastic honeycomb panels. Plastic honeycomb panels are a branch product of honeycomb panels and are the lightest in the honeycomb panel series.

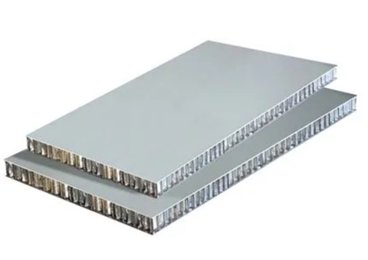

Aluminum honeycomb panels paper honeycomb panels

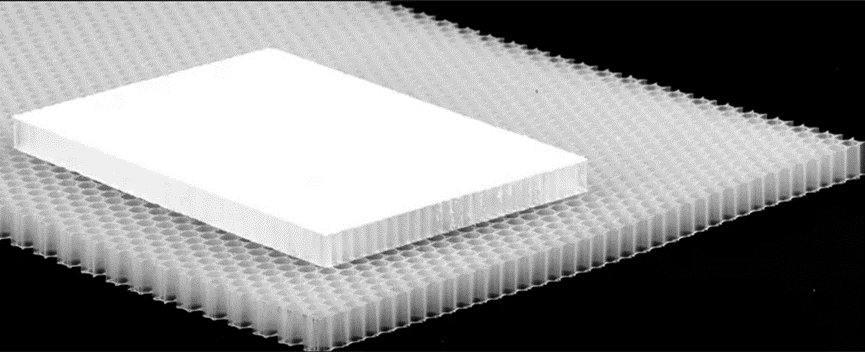

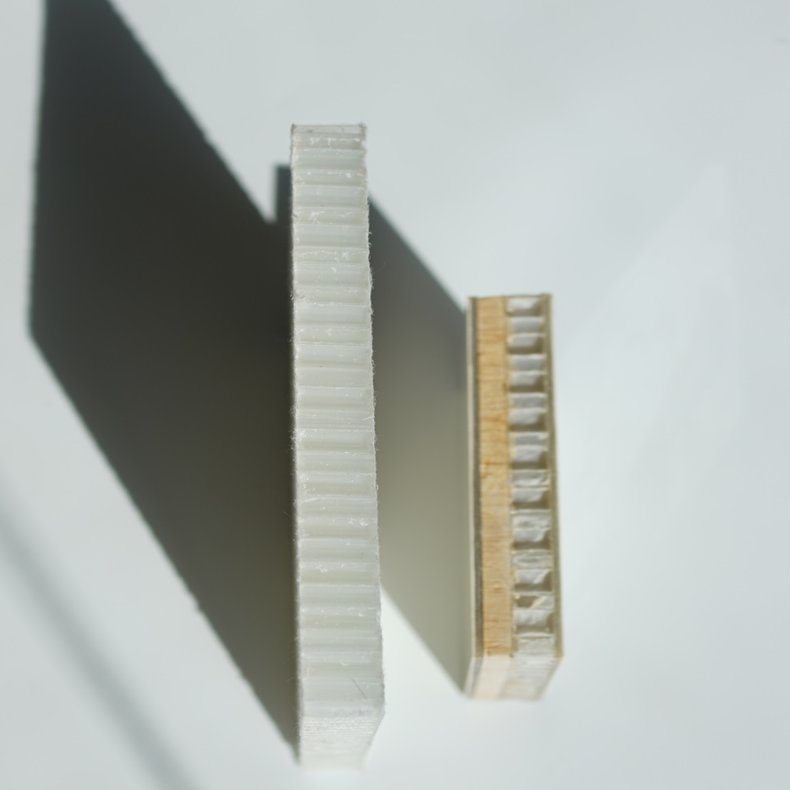

Honeycomb panel is a board made of two thin panels firmly bonded to both sides of a thicker honeycomb core material. Honeycomb core material is composed of a series of hexagonal, quadrilateral or other shapes of honeycomb cells (our company uses round hole honeycomb core), and thin panels are glued to the upper and lower sides of the sandwich layer/ The skin, panels and core materials are firmly bonded together, showing the excellent characteristics of honeycomb panels, that is, they have multiple functions such as high specific strength, low thermal conductivity and good shock resistance.

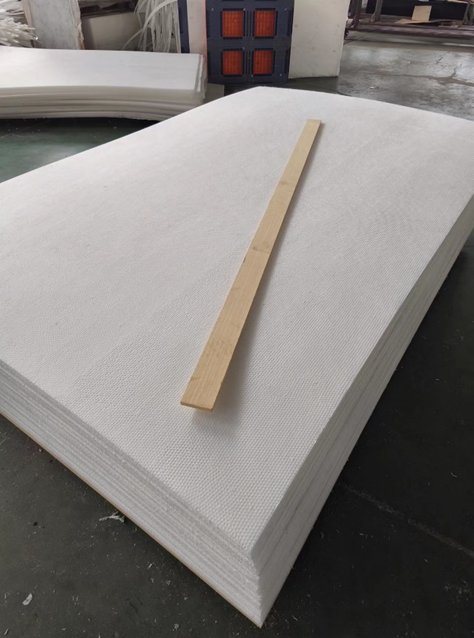

Plastic honeycomb panels

2. Classification of our company's plastic honeycomb panels

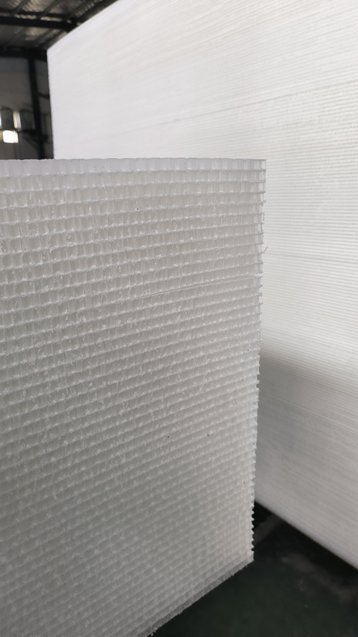

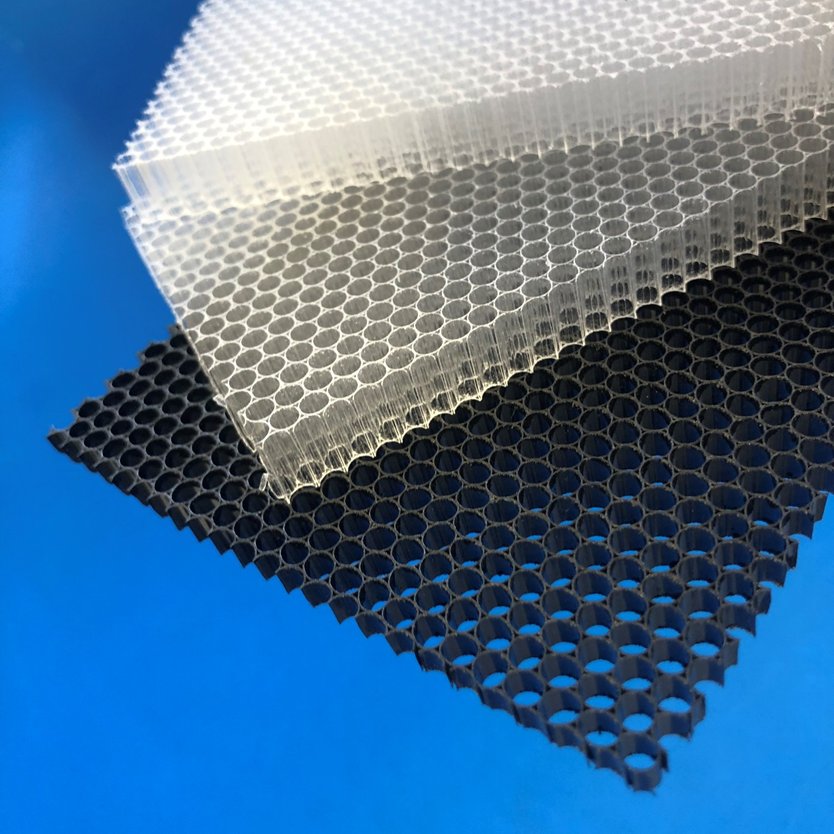

Our honeycomb panel products mainly include PP (polypropylene) honeycomb and PC (polycarbonate) honeycomb. Can be made into hollow panels of different specifications. You can choose any colour and specification according to your needs. The commonly used colour of the PP honeycomb core is white, and the PC honeycomb core is transparent, black and grey. The cell sizes of PP honeycomb panels are generally 6mm, 8mm, and 10mm. The PC honeycomb cores cell sizes are generally 3.5mm, 6mm and 8mm. The standard size is (4 ' X8 ' )1220*2440mm, and the thickness can be customized from 5mm to 500mm. PP (polypropylene), and PC (polycarbonate) have good plasticity and are some of the most popular raw materials in honeycomb panels.

Each cell of the plastic honeycomb has a tubular structure. The countless tubes make it evenly and stably stressed. Its main features are lightweight, high strength, thermal insulation, sound insulation, water resistance, moisture resistance, corrosion resistance, non-toxic and harmless, antibacterial and antibacterial. Mildew, environmentally friendly, pollution-free easy to process, energy-saving, affordable, widely used, reasonable combination, good thermal performance and electrical insulation.

3. Application of plastic honeycomb panels:

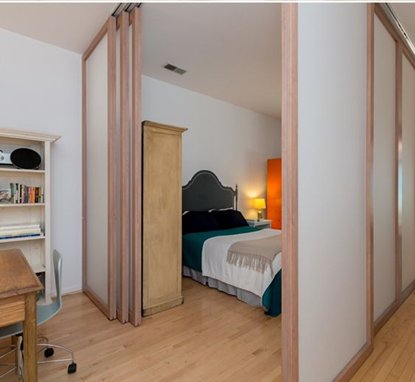

There are two types of polypropylene honeycombs: open cell and composite non-woven surface honeycomb panels. PC and PP honeycomb cores with open cells are mostly used in filter ventilation systems and laser cutting machine pads due to their smooth and uniform pore diameters and flat surfaces and are also used in soft light systems. PP non-woven surface honeycomb panels can be composite with different materials such as steel plate, aluminium plate, fibreglass, paper board, thin marble, and other high-strength composite materials. Its raw materials are environmentally friendly and recyclable, protecting the ecological environment, and are light and strong. , stable, thermal insulation, heat insulation, shockproof and many other advantages. PP honeycomb composite panels are widely used in ships, yachts, ports, bridge construction, truck bodies, buildings, fibreglass, etc.

If you are interested in plastic honeycomb panels or have new application ideas, please contact us. Our company can provide free samples to test.