If you want to build a boat/craft, First you must study the Interpretation and construction standards for Small craft Hull construction and scantlings from the International Organization for Standardization.

The Reference documents: ISO 12215-5:2008,

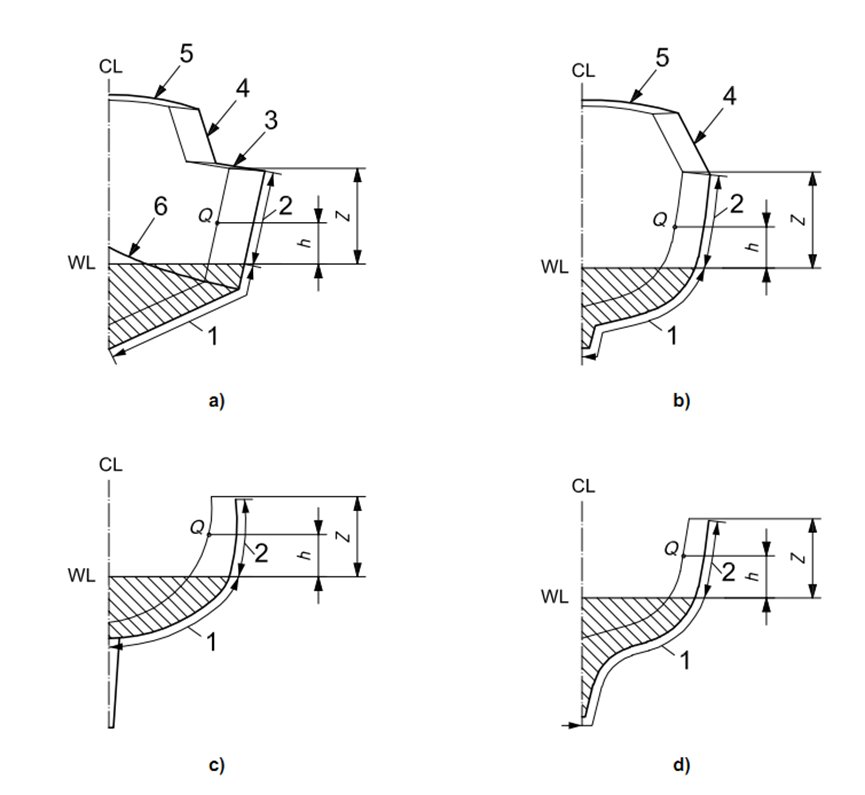

This information contains Design pressures for monohulls, design stresses, scantlings determination

Plastic honeycomb panels are lightweight, high strength, water resistant, moisture resistant, heat preservation, sound insulation, corrosion resistant, non-toxic and harmless, preventing bacteria and mildew. It also has the characteristics of energy absorption, thermoplastic re-deformation and impact absorption, making it very suitable for use as marine materials in the water.

As a Chinese plastic honeycomb panels factory, We have focused on plastic honeycomb-related products for decades. we have our quality inspection department. Whether it is the control of the production process or the testing of finished products, we strictly control quality and tolerances based on customer requirements and data.

Our company supplies non-woven plastic honeycomb cores to yacht manufacturers year-round. This panel can be composite with many surface materials to meet different design of appearance and interior requirements especially used for FRP composite honeycomb panels. Besides, the honeycomb cellular structure have the functions of sound insulation, noise reduction and heat preservation. Ideal for the manufacture of lightweight boat hulls, interior cabinets and small craft etc. Honeycomb core size, thickness and cell size can be customized. For more product information, please browse our product list or leave us a message.