Plastic(pp/polypropylene) honeycomb core has the features of light weight/high strength, heat insulation, anti-knock/absorb energy, soundproof/sound absorb, waterproof/ corrosion prevention, eco-friendly and odourless. Is very suitable for the pickleball paddle.

1. lightweight: Polypropylene material is a lightweight plastic that makes PP honeycomb rackets lighter than traditional pickleball rackets, helping to improve the racket's control and flexibility.

2. honeycomb core structure: The honeycomb structure racket uses a honeycomb grid structure inside the racket surface, which can improve the strength and stability of the racket to a certain extent while reducing vibration.

3. Durability: The pearl material has good wear resistance and durability, allowing the PP porous ball to withstand a certain amount of hitting impact and use time, extending the service life of the racket.

4. Adaptability: PP honeycomb racket is suitable for players of different levels, from beginners to amateurs, and has good adaptability.

5. Affordable: Compared with pickleball rackets made of some high-end materials, PP honeycomb rackets are usually more affordable and suitable for ordinary consumers to buy.

5. Achieving pickleball racket/paddle plastic honeycomb core

Qingdao Achieving Honeycomb Panel Co., Ltd. is a factory specializing in the production of plastic honeycomb-related products. The polymer pickleball racket core provided by it is a honeycomb structure with multiple round holes. The hole size is uniform so that the racket is evenly stressed. And has high surface flatness, Moisture-proof, waterproof, low noise, good sound-absorbing performance and excellent elasticity. The size and strength of the honeycomb can be adjusted to suit the strength of the pickleball attack. The price is suitable for civilian consumption. While being as light as possible, it maintains rigidity and gives the pickleball a good rebound height.

1. Import raw materials, non-toxic and recyclable

The raw material of honeycomb core material is brand-new polypropylene raw material, which is safe, non-toxic and formaldehyde-free, and complies with modern environmental protection standards. The material can be recycled and reused.

2. Customized service

We have specialized technical staff to study the data which is provided by customers. Whether it is the wall thickness, cell diameter, thickness, size or surface material of the honeycomb panel, we can provide customized services.

3. Short lead time and abundant logistics experience

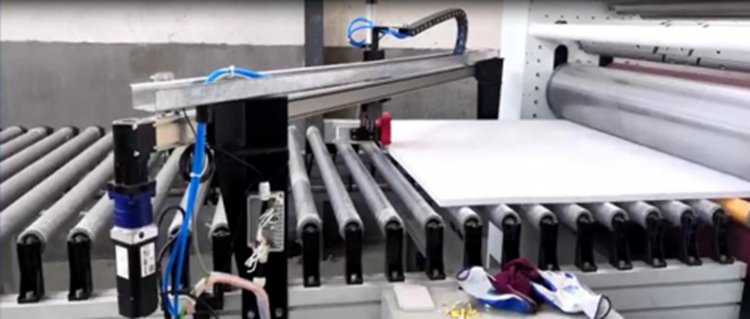

The automated assembly line operation of honeycomb panel manufacturing has been realized using self-developed equipment. Orders can be completed quickly and within a short period, with guaranteed delivery dates.

4. Best quality and tolerance control

As a factory, we have our quality inspection department. Whether it is the control of the production process or the testing of finished products, we strictly control quality and tolerances based on customer requirements and data.