Many materials can be composited with plastic honeycomb core panels. The common ones are:

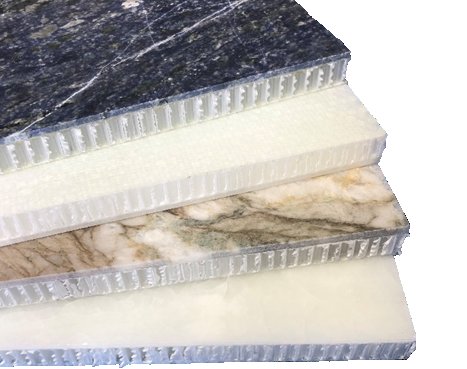

1. Stone honeycomb composite panel

Natural stone with a surface thickness of 3-5mm uses a lightweight plastic honeycomb as the base material, which completely overcomes the shortcomings of natural stone. Stone plastic honeycomb composite panels not only maintain the green, environmentally friendly, and return-to-nature fashionable decorative effects of natural stone, but also overcome the shortcomings of natural stone, such as its high brittleness and heavy decorative weight. The medium between the ultra-thin stone sheets and the honeycomb is a high-strength fibre transition layer, which makes the product have stronger impact resistance and flexural strength. At the same time, it is filled with air inside, is extremely light in weight, and has good sound and heat insulation effects.

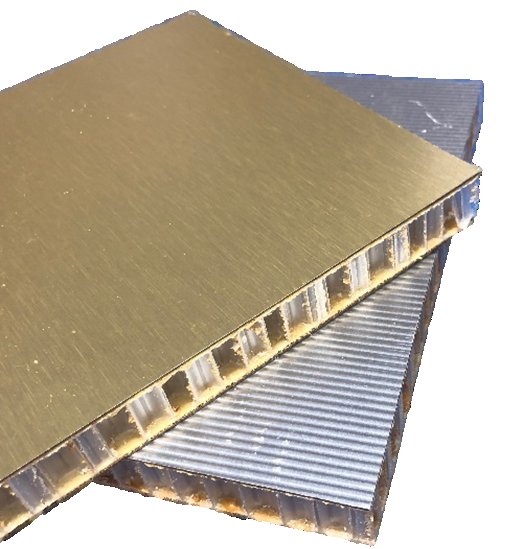

2. Metal surface honeycomb composite panel

It adopts a "honeycomb sandwich" structure, which is a composite plate made of high-strength alloy aluminium plate as the surface, bottom plate and plastic honeycomb core through high temperature and high pressure. It has the characteristics of lightweight, high strength, good stiffness, strong corrosion resistance and stable performance. Features. Since the air layer between the surface and the bottom panel is divided into numerous closed holes by the honeycomb, the propagation of heat and sound waves is greatly restricted. Compared with other curtain wall decoration materials, metal-faced honeycomb panels have good thermal insulation and thermal insulation properties.

3. Wooden honeycomb panel

It is made of natural wood veneer with a thickness of 0.3-0.4mm and high-strength plastic honeycomb panel. Features of wooden honeycomb panels: retaining the decorative texture of natural wood, lightweight, less wood usage, corrosion resistance, pressure resistance, etc.; at the same time, through special processes such as wood parquet, parquet, and perforation, it provides designers with more design inspiration.

4. Fabric honeycomb panel

It is made of different styles of facing fabrics and honeycomb panels and is mainly used for indoor walls. With traditional wall covering decoration, moisture on the wall will cause the wall to bulge and become mouldy, and the corners of the wall are more likely to warp. Fabric honeycomb panels can effectively avoid the above problems. Not only do they have high flatness, but also with a dedicated interior wall system, each wall panel can be individually disassembled and assembled, making it more convenient for future maintenance and reuse.

5. Fiberglass honeycomb panel

It is made of 1-2mm fibreglass and honeycomb panel. The fiberglass surface material will greatly increase the high strength of the honeycomb panel, and reduce the weight of the same strength panel by about two-thirds, greatly reducing transportation costs and various traffic conditions—the weight of the tool.