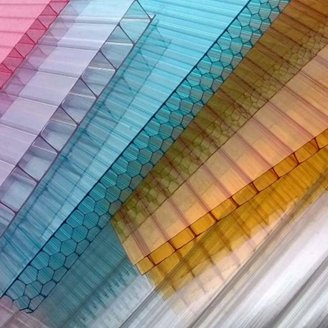

PC is a plastic material with perfect toughness and practicality. It has the characteristics of light weight, high transparency, good impact resistance, good dimensional stability, weather resistance, good electrical insulation properties and easy to shape. PC honeycomb panels and PC hollow panels are both made of this material with similar outlooks, but there are big differences in uses and characteristics. What is the difference between PC hollow board and honeycomb board?

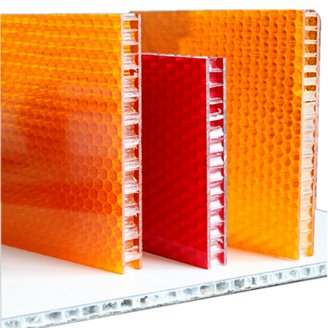

PC honeycomb panel with acrylic covering PC hollow board

1. Differences in structure

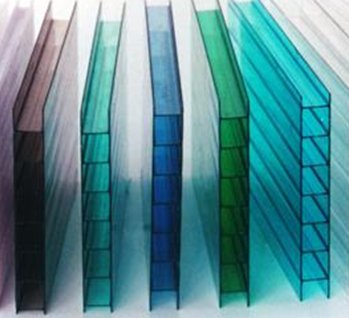

PC hollow board is an extruded panel at high temperature. The middle cross-section will appear in a grid shape, it is also called greenhouse roof board, hollow grid board, etc. It is a new material that is environmentally friendly, pollution-free and rich in color. The panels have at least two walls and are thermally insulated.

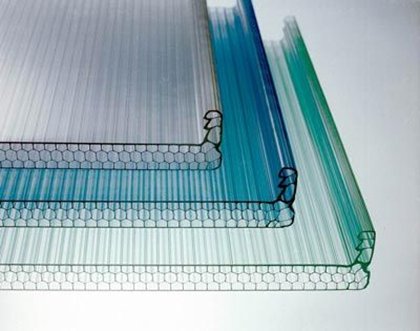

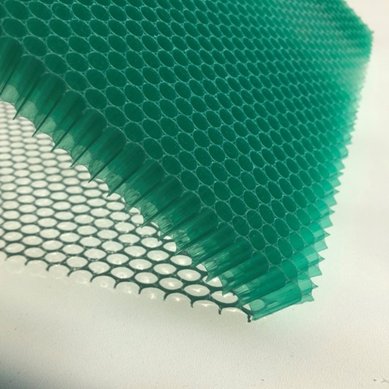

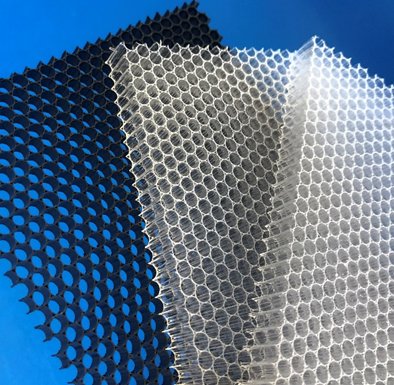

PC honeycomb panels are composed of round hole-shaped honeycomb cores that are closely arranged and connected to each other, just like countless I-beams. The layer cores are distributed and fixed in the entire panel. Its surface can be compounded with decorative materials such as acrylic, which not only increases the beauty but also makes each closed, adding a sealing effect.

2. Differences in performance:

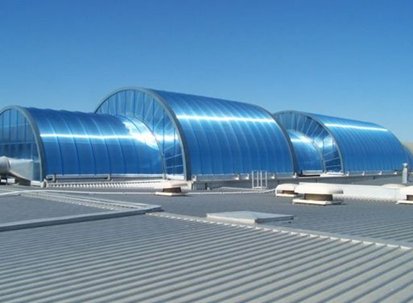

Polycarbonate hollow panels are better at insulating than solid panels because they trap air within their hollow structure, acting as an excellent thermal barrier. It has good transparency, impact resistance and weather resistance, and can provide good light transmittance, filling the room with natural light. At the same time, it can effectively block the intrusion of ultraviolet rays and protect indoor items from damage by ultraviolet rays.

PC honeycomb panels are not only the lightest among other materials of the same volume due to their unique structure but also have excellent hardness and overall stability. Polycarbonate is neither radioactive nor evaporates any harmful gases that are harmful to human health. It can be completely recycled and reused, saving resources and energy, and minimizing environmental pollution. This makes PC honeycomb panels a new material of energy-saving, environmentally friendly and healthy.

3. Differences in application:

PC hollow board has good transparency, so it is widely used in construction, billboards, lighting skylights and other fields. In addition, polycarbonate hollow panels also have good thermal insulation properties and can effectively reduce the energy consumption of buildings. Widely used in greenhouses, parking sheds, channel lighting ponchos, residential buildings, commercial building lighting canopies, exhibition lighting, sports venues, swimming pools, warehouse lighting roofs, lighting ceilings and sunshade awnings of businesses, factories, sports venues, agricultural greenhouses, breeding industries and flowers Greenhouses, as well as telephone booths, newsstands, stations and other public facilities.

PC honeycomb core is a typical porous structure. The continuous cells are arranged in a regular periodic manner. Therefore, the cross-sectional area of the solid part of the honeycomb panel is very small, so its density is also very small compared to other sandwich materials. PC honeycomb Can be cut into rounds or designed shapes and installed into lighting systems for a unique lighting look. Extremely high surface flatness and strict thickness tolerance control can be applied to backing plates for laser cutting machines, air curtains, air and water filtration systems, diversion systems, curtain wall decoration, interior decoration, roofing materials, interior decoration, partition and other construction and decoration industries.

Honeycomb core acrylic composite panels

for indoor partitions PC honeycomb panel for protective gear