Pros:

1. Plastic honeycomb panels offer superior acoustic properties as they effectively absorb sound at mid-frequency and higher ranges. In contrast, plywood reflects sound waves, rendering it ineffective for noise reduction, particularly in industrial and building settings.

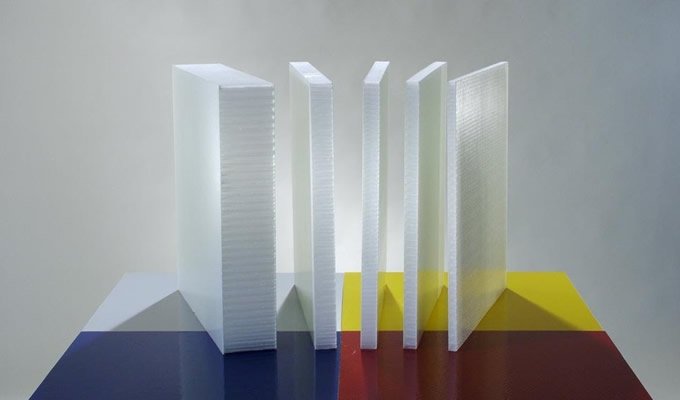

2. Honeycomb sandwich panels typically consist of thin composite laminates, created by incorporating glass fiber unidirectional strips into a polypropylene matrix. The honeycomb cores are commonly made from polypropylene thermoplastic resin. These panels possess significant strength while being 60% lighter than plywood. The substantial weight difference makes honeycomb panels easier to transport and more cost-effective compared to plywood. Thermoplastic honeycomb has an important advantage in resisting pests: termites, wood ants, beetles, and other pests can corrode wood and cause widespread damage. Plywood does not have any moisture resistance and is not suitable for outdoor use.

3. Recent advancements have enabled the fully automated production of polypropylene honeycomb panels. This results in significant cost advantages and competitive pricing for the product. The panel combines the benefits of polypropylene-based composite materials and a honeycomb structure, offering exceptional bending stiffness and impact strength at a significantly reduced weight.

4. Plywood is regarded as unsustainable due to the presence of formaldehyde or phenolic-based glues used to bind the veneer layers. These glues render wood non-recyclable and difficult to burn due to their toxic properties. Moreover, plywood production environments may have toxicological safety concerns, as plywood has been linked to cancer risks. The growing demand for recyclable materials has spurred the development of cost-effective and sustainable versions of core cellular technology. Polypropylene honeycomb panels emerge as a superior alternative to plywood, as they are highly sustainable, lightweight, and fully recyclable.

Cons:

5. Plywood exhibits better-bending resistance than honeycomb composite boards. In structural areas requiring load-bearing capabilities, plywood offers greater strength. However, for most applications, the bending resistance of fiberglass honeycomb composite panels is sufficient to meet requirements.

6. Plywood boasts a strong nail grip, facilitating convenient construction, and is less susceptible to warping. Its transverse tensile strength surpasses that of honeycomb boards.

7. Plywood withstands high temperatures and weather conditions after being boiled in water, making it durable and less prone to damage. However, honeycomb core materials are less resistant to high temperatures than plywood, and their weather resistance and durability rely on the composite materials used on their surfaces.

8. Plywood possesses the aesthetic advantages of natural wood, making it widely used in furniture applications with its beautiful texture and clear lines. Honeycomb composite panels, on the other hand, have certain limitations regarding their coating materials.