In most primary and secondary school classrooms as well as office spaces, bare lighting fixtures are commonly used. However, the direct light emitted by these fixtures often creates glare, which can have a negative impact on the human eye, causing discomfort and visual fatigue. Glare can be classified into two categories based on its effect on visual function: dysfunctional glare and psychological glare. Dysfunctional glare physiologically impairs vision and affects the visual organs, while psychological glare, when experienced for prolonged periods, leads to feelings of discomfort and psychological distress. Severe glare can strain the eye muscles, causing distraction, difficulty in focusing, and significant damage to eyesight, particularly during the growth and development stages of adolescents.

Glare is a visual phenomenon that occurs when the brightness of a light source is excessively high or when there is a significant difference in brightness between the background and the central field of view. This phenomenon not only hampers visual perception but also contributes to visual fatigue. Anti-glare measures aim to effectively reduce this undesirable visual phenomenon.

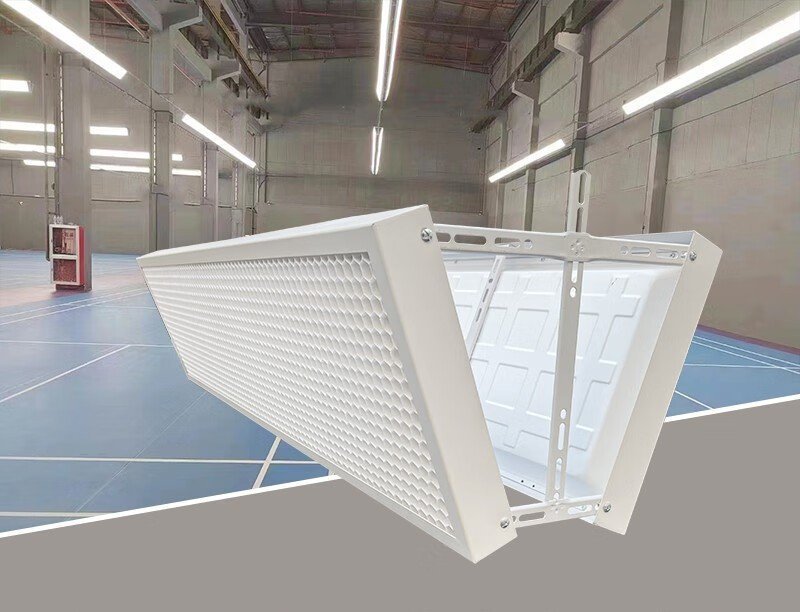

To mitigate the visual impact of glare on individuals, conventional methods often employ uniform grilles to address the issue. The longitudinal and transverse partitions of the grille obstruct and scatter light within the line of sight, increasing the shading angle and preventing direct light from shining into the human eye. This approach achieves the objective of glare reduction. More grille strips provide better anti-glare effects, but they result in reduced light efficiency. Conversely, fewer grille strips can increase light efficiency but offer poorer anti-glare performance. In light of this, a honeycomb anti-glare optical component is proposed.

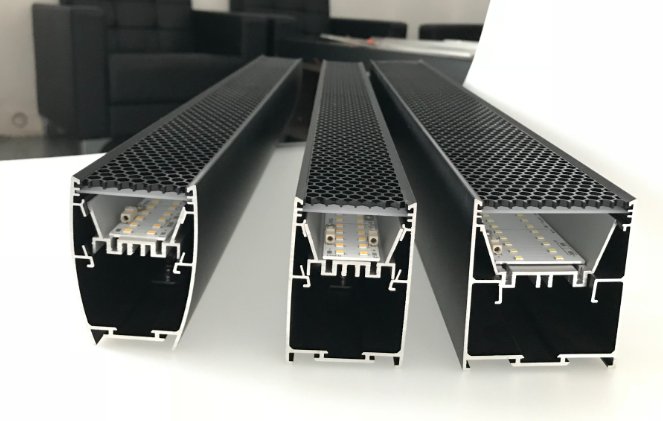

Honeycomb anti-glare involves the incorporation of a honeycomb plate within the lampshade to act as a shield, reducing glare leakage. The addition of the honeycomb mesh serves two primary purposes: first, to prevent glare, and second, to block the luminous surface and disperse the strongly radiated light columns from spotlights. The honeycomb mesh subdivides the light into smaller columns, resulting in a softer illumination that is less harsh on the eyes. The use of a black anti-glare honeycomb mesh involves integrating a three-dimensional honeycomb mesh in front of the reflector (lens). This effectively divides the non-reflective material layer into multiple small areas, redirecting the afterglow to the sides of the black honeycomb mesh and reducing the occurrence of reflected afterglow.

Qingdao Achieving Honeycomb Panel has been dedicated to the production of honeycomb core materials for the past 20 years. They currently offer white and black polycarbonate honeycomb cores for applications requiring anti-glare functionality, such as LED lighting. The standard cell sizes available are 3.5mm, 4mm, 6mm, and 8mm, with thickness options ranging from 5mm to 500mm. Cutting services are available for round, square, and elongated shapes, and inclined honeycomb cores or inclined cut surfaces can also be produced to meet specific requirements.