Introduction

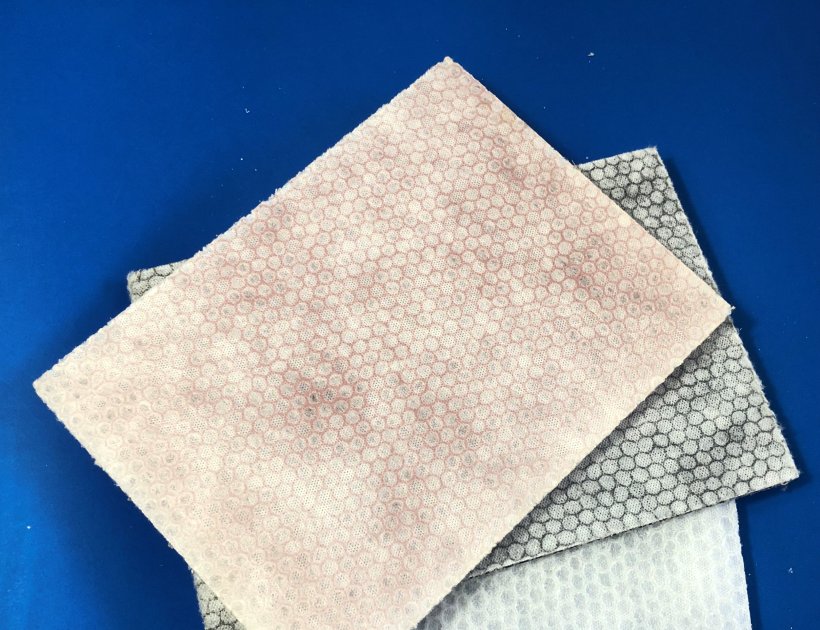

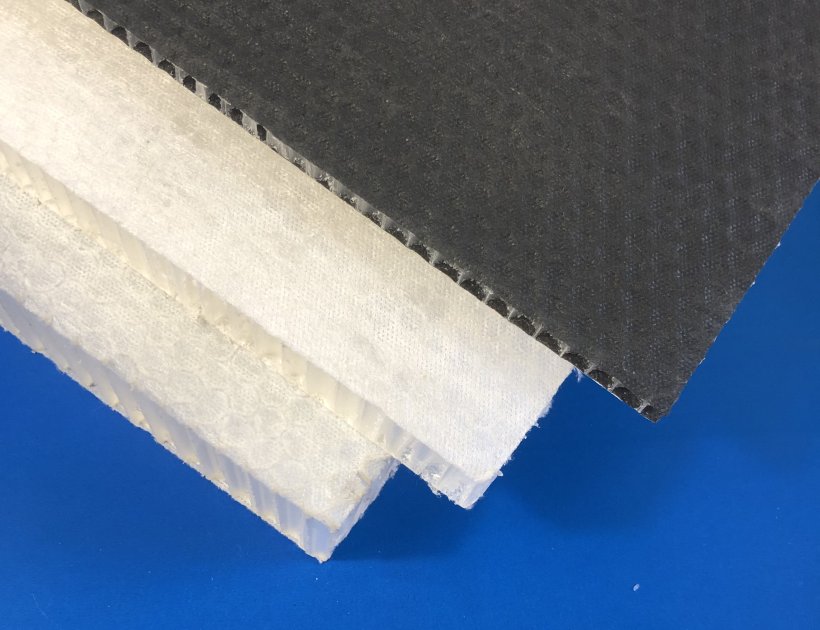

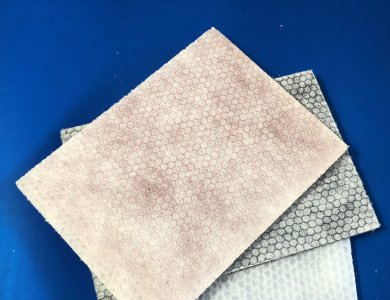

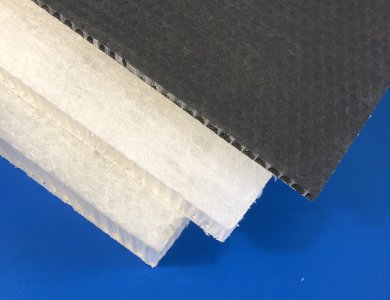

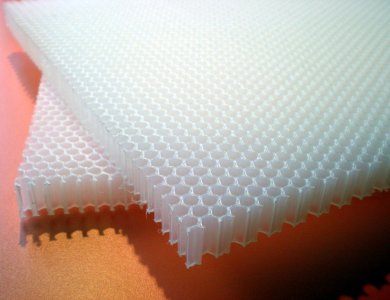

Achieving polypropylene honeycomb core is made from high-quality raw material. The Highly automated equipment ensured in our factory can minimize the tolerance. The non-woven fabric on top of the honeycomb facilitates subsequent plate processing. Polypropylene honeycomb core can be used in furniture and interior design for lightweight and modular structures. It allows for innovative and customizable designs while reducing the overall weight of the furniture pieces. In the marine industry, polypropylene honeycomb core is utilized for boat hulls, bulkheads, decks, and furniture. Its resistance to water and moisture, combined with its lightweight nature, makes it an ideal material choice for marine applications. In construction and architecture, polypropylene honeycomb core is employed for lightweight cladding panels, partitions, false ceilings, and furniture. Its strength-to-weight ratio makes it suitable for applications where weight reduction is desired without compromising strength and rigidity. The automotive industry utilizes polypropylene honeycomb cores for lightweight panels and structures in vehicle interiors, such as door panels, headliners, trunk liners, and parcel shelves. It helps to reduce weight while maintaining structural integrity and sound insulation. The honeycomb structure of polycarbonate cores provides inherent thermal insulation properties. They can be used in applications where thermal management is important, including building facades, refrigerated transportation, and HVAC systems.

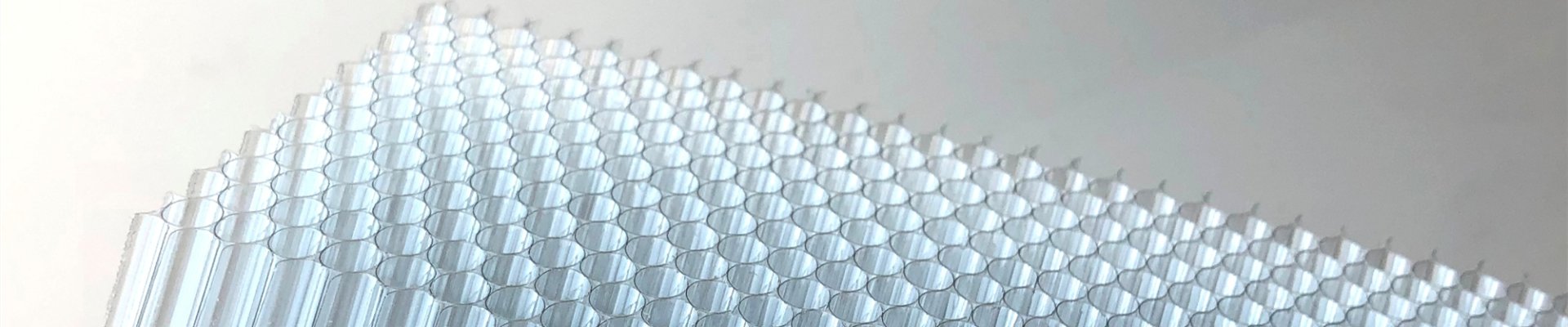

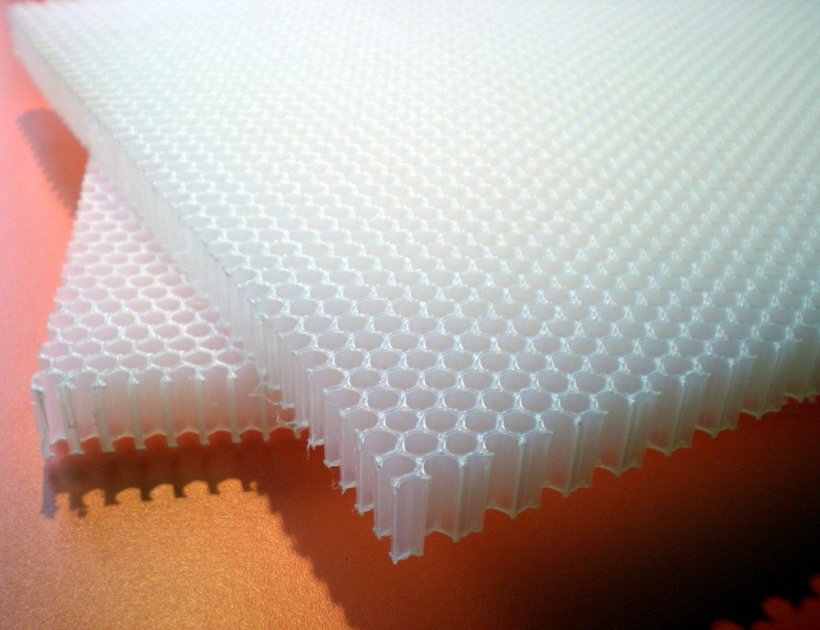

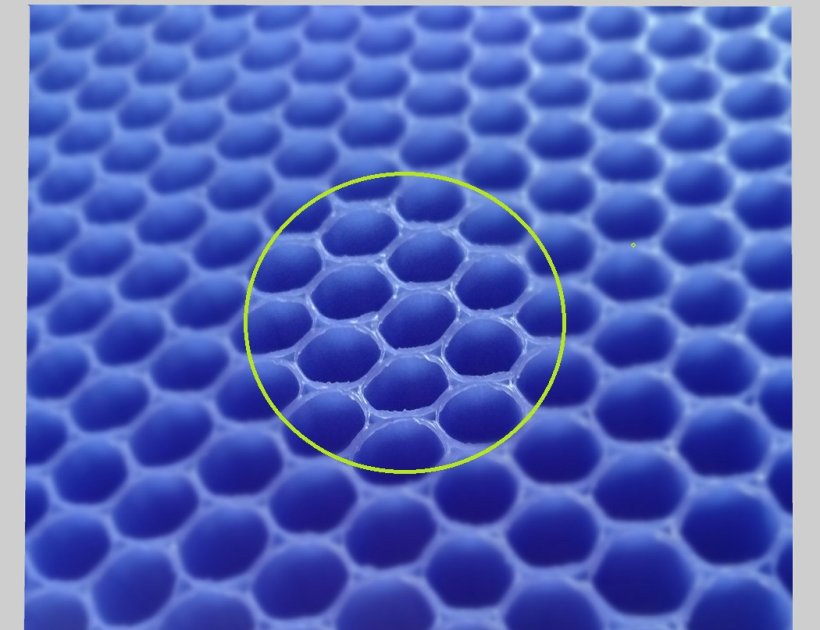

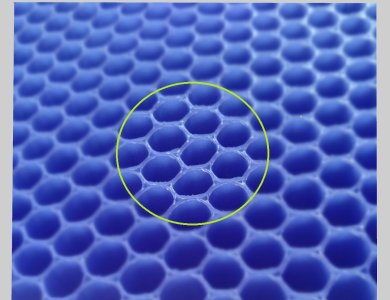

The 6/8/10/12mm cell diameter is our standard product, which doesn't require for a high MOQ. The common density is 80kg/m³ and it will change with the cell size, please check the technical data for more information.

It is used in boats, yachts, buildings, truck/van/caravan bodies, sandwich floors, sandwich wall panels, partitions, furniture boards etc.

Specification

Standard size 1220*2440mm, maximum size 1500 mm*3000 mm.

Standard colour is White.

Stabdard tolerance is ±0.3mm.

Standard cell sizes are 6mm/8mm/10mm.

Standard density is 80kg/m³ (cell size 8mm), and the density will change with the cell size, please check the technical data for more info.

Standard thickness 4mm to 50mm or customize.

Standard leading time will be 20 workdays for 20ft' containers.

Application

In the marine industry, polypropylene honeycomb core is utilized for boat/yacht hulls, bulkheads, decks, and furniture. Its resistance to water and moisture, combined with its lightweight nature, makes it an ideal material choice for marine applications. It also is inherently resistant to corrosion, making it suitable for use in environments that are exposed to moisture, chemicals, or salt water. Unlike metal honeycomb cores, plastic honeycomb does not rust or corrode, ensuring the longevity and durability of the sandwich panel in marine, coastal, and chemical processing applications.

Polypropylene honeycomb is exceptionally lightweight, which makes it an ideal core material for sandwich panels. By incorporating Polypropylene honeycomb, sandwich panels can achieve a high strength-to-weight ratio, providing structural integrity without adding significant weight. The honeycomb structure consists of multiple cells that distribute loads efficiently, enhancing the overall strength of the sandwich panel. This enables the panel to withstand external forces and stresses, making it suitable for demanding applications and it allows for the dissipation of energy by deforming and collapsing under impact.

Besides, Polypropylene honeycomb can be easily customized and fabricated to meet specific design requirements. It can be cut, shaped, and moulded into various sizes and shapes, allowing for flexibility in panel design. This enables the creation of complex geometries and innovative structures, making it suitable for applications that demand design freedom and versatility. Which makes it the perfect inner material for your ideal sandwich panel. Such as roof tent boxes, cargo car bodies, ship interiors, swimming pools, photovoltaic power generation, high-speed rail, aviation, high-pressure oil pipelines, drywall decora wall coat, furniture board, load-bearing plates, and tables.