Honeycomb core material is a monolithic core material made of PC (polycarbonate), PP (polypropylene), aluminium, etc., which is processed and bonded into a hexagonal or circular hollow (honeycomb shape). Commonly used panels are PC, PMMA, PETG, aluminium, etc. The panels must be firmly bonded with the core material using appropriate adhesives to demonstrate the excellent properties of honeycomb panels, which include high specific strength, low thermal conductivity and good earthquake resistance.

Function: Plastic honeycomb panels are divided according to their material: Polypropylene(PP) honeycomb panels and Polycarbonate(PC) honeycomb panels.

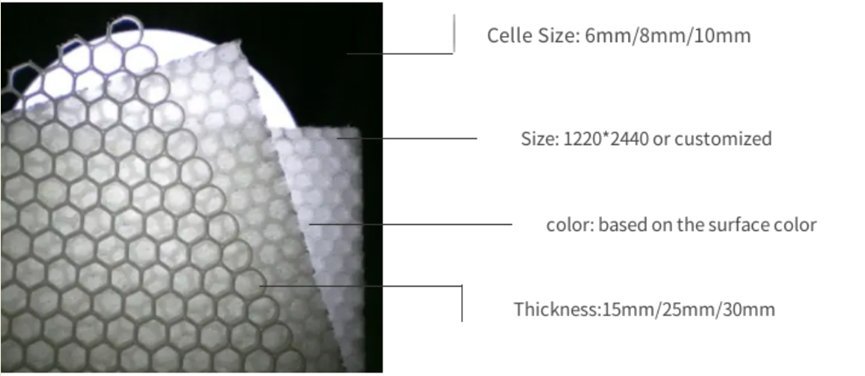

Due to its special structure, it can improve the compressive strength and reduce the cost of plastic honeycomb panels. Honeycomb panel cell sizes are generally divided into (circular) 6mm, 8mm, and 10mm; PC honeycomb core 8MM. Plastic honeycomb panels can be used to make billboards, pickleball paddles, walls, ceilings, decorative panels, light boxes, etc. Plastic honeycomb panel is a new green decorative material emerging in developed countries this year that saves resources, protects the ecological environment, and is low-cost. It has many advantages such as lightness, strength, stability, heat preservation, and heat insulation.

Features: The characteristics of honeycomb panels are a large strength-to-weight ratio, average stress, strong pressure resistance, low thermal conductivity, good shock resistance, lightweight, sound insulation effect, non-water absorption, and stable performance in a wide temperature range.

Features:

1. The plate has high flatness

2. Large-area plates can be realized

3. Honeycomb core material contributes to the thermal insulation effect of the space

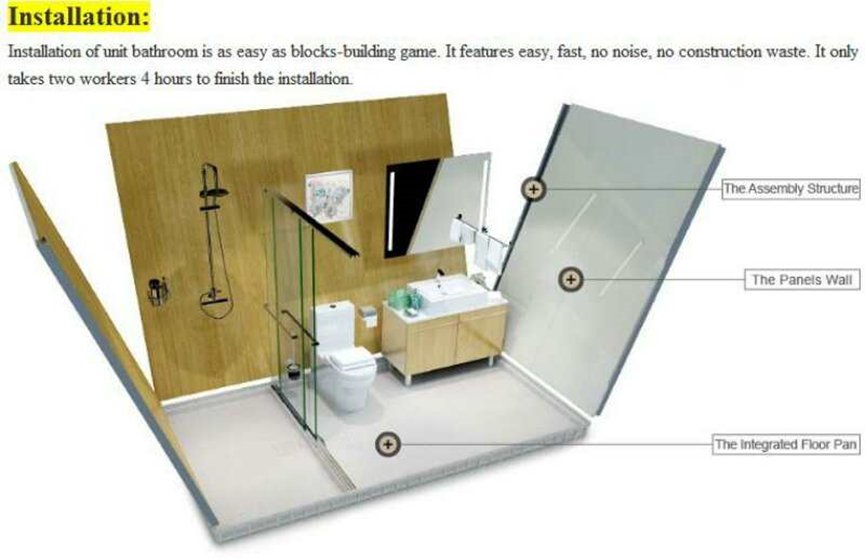

4. Easy and quick installation

5. The board is light in weight and high in strength.

6. High-quality materials and advanced processing technology ensure the durability of honeycomb panels.

7. Rich colours and surface treatments to choose from