Ⅰ. Functions and characteristics of honeycomb platform of laser cutting machine

The honeycomb platform is an important part of the laser-cutting machine. It can support the material being cut and avoid deformation or excessive deformation due to heating. The characteristics of the honeycomb platform are that it can fix the material and discharge the waste through the honeycomb holes while reducing the quality of the material and reducing the cutting time and cost.

Ⅱ. Advantages and disadvantages of honeycomb platforms made of different materials

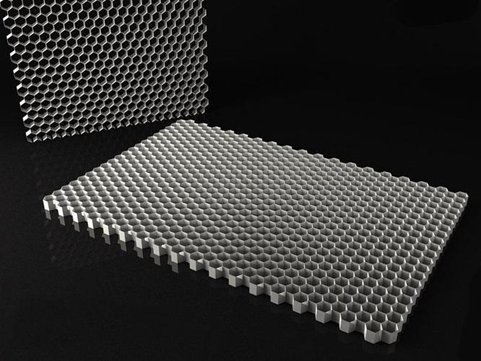

1. Aluminum alloy honeycomb platform

Aluminium alloy honeycomb platform is a common material with advantages such as light weight, durability, and easy processing. In addition, the aluminium alloy also has good thermal conductivity and can withstand high temperatures without deformation, so it is widely used in laser-cutting machines. However, this material is susceptible to mechanical damage, corrosion, and high cost.

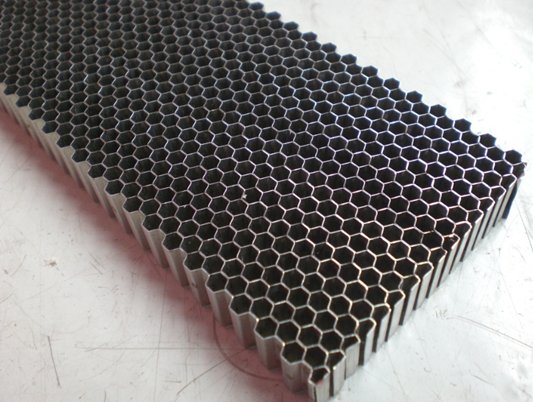

2. Stainless steel honeycomb platform

The stainless steel honeycomb platform is a material with strong antioxidant properties. It has the advantages of being easy to clean and not easy to deform. The polished surface can effectively prevent the material from being scratched, but it is easily affected by moisture and has corrosion problems, so the price is relatively high.

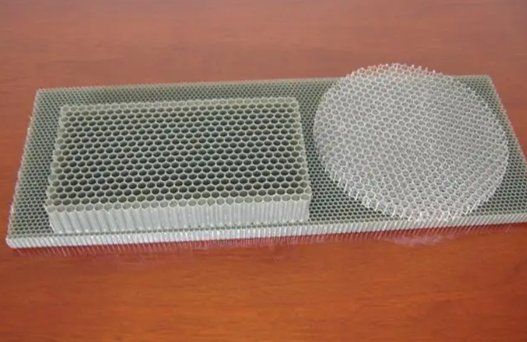

3. Ceramic honeycomb platform

The advantages of a ceramic honeycomb platform are good thermal conductivity, high hardness, resistance to deformation, and strong chemical inertness. It can be used for a long time without polluting the material. However, the platform is expensive and fragile and needs to be replaced once it is damaged.

4. PC(polycarbonate) honeycomb core platform

The PC honeycomb platform is a round hole core, the core unit is tightly fitted and has the characteristics of uniform pore size, stable structure, small thickness tolerance, and smooth surface. At the same time, it meets the laser cutting machine requirements of low sputtering rate, low gas absorption rate, top flatness and strong air permeability. The PC honeycomb core is tightly fitted, which can provide excellent compressive strength, working temperature -40℃ to +110℃, easy installation, can keep clean for a long time, and has a long service life. The biggest feature is the low price and high-cost performance.

Qingdao Achieving Honeycomb has been committed to producing PC honeycomb cores for nearly twenty years. At present, it has realized automated production technology, high production efficiency, a short cycle, strict tolerance range control, a flat surface, a round aperture, and standard apertures of 3.5mm and 6mm. The size and thickness can be customized according to machine adaptation. If you are interested, please consult.

Ⅲ. How to choose the right cellular platform material for you

To choose the right honeycomb platform material, you need to consider various factors, such as the cutting material's type and thickness, the cutting machine's power, the production batch's size, etc. You can also consider the cutting effect, durability, and price, and then choose the material that suits your production needs.