Have you ever been kept up all night because of the noise next door downstairs? Or can't rest because of the noise coming from the floor? If you have such a problem, then you need to know about floor sound insulation, good floor soundproofing can effectively reduce the noise transmission, so that you can rest at ease!

At present, the main sound insulation material products on the market include damping sound insulation panels, honeycomb sound insulation panels, composite sound insulation panels, sound insulation bricks, sound insulation felts, sound insulation cotton, etc.

1. Sound insulation felt:

Sound insulation felt is a better room soundproofing material currently on the market. It is mainly used to match with gypsum board for wall sound insulation and ceiling sound insulation and is also applied to sound insulation and vibration damping of pipes and mechanical equipment. Acoustic felt is not felt, it looks totally different in appearance, felt is light and soft, while acoustic felt is thin but heavy.

Sound insulation felt has a certain sound insulation effect due to its damping characteristics and newly improved sealing performance. It is very popular in low-insulation structural buildings. After being matched with gypsum board, it is widely used in residential buildings, entertainment, offices, and industrial places. If you often exercise at home or listen to music and watch TV, then you can use soundproofing felts on the walls, ceilings, and floors of your home to be fully armed! Sound insulation felt has a certain degree of flexibility, high density, and heavy material. It is not easy to cause resonance, and it also has a certain effect on shock absorption!

However, most Sound insulation felt on the market does not meet environmental protection standards. These inferior products are mixed with too many harmful additives such as plasticizers during the production process. Not only the sound insulation effect is poor and easy to break, but also cannot be degraded, when combustion it is also toxic smoke, so it brings great harm to the human body. The price of high-quality sound insulation felt is very expensive, and the better one is USD45 dollars per square meter, which shows the high price!

2. Sound insulation cotton:

Sound insulation cotton is made of fiber-porous sound insulation materials. These materials have excellent sound insulation properties and can effectively isolate the propagation energy of sound. Fiber porous sound insulation materials include polyester fiber wool, centrifugal glass wool, rock wool, mineral wool, plant fiber spray, etc. There are a large number of tiny connected pores inside their materials, which can convert sound waves into heat energy and effectively reduce the spread of sound. Sound insulation cotton has many advantages. In addition to effective sound insulation, it can also have heat insulation and moisture-proof functions. Its service life is very long because it is directly nailed to the wall or stuffed into the keel, so there is no There is cracking. Sound insulation cotton also has a flame retardant effect, and its flame retardancy rate reaches the B1 level. Because the sound insulation cotton is very light, it is easier to construct and can be used twice.

The raw material of sound insulation cotton is made from asbestos. Asbestos is very harmful to the human body because its fibers are very thin and are more likely to cause a series of lung diseases after inhalation. Moreover, it has a certain incubation period and will accumulate for a long time before bursting out. This incubation time could be as long as ten or twenty years.

3. Shock-absorbing bricks:

Floor shock-absorbing tiles are flooring materials that can slow down ground impact and reduce noise. It is mainly made of polypropylene and elastomer materials. Polypropylene is a polymer material with strong toughness and flexural strength, and elastomer can provide better elasticity and elastic recovery rate, thereby slowing down ground loosening and reducing noise.

Floor shock-absorbing tiles have many features. First, it is easy to use and easy to install. Secondly, it has excellent shock absorption and noise reduction effects, which can effectively avoid disturbances to the surrounding environment and residents caused by earthquakes, subways, airports and other large-scale projects. In addition, the floor shock-absorbing bricks are also corrosion-resistant, waterproof, and wear-resistant, which not only protects the ground environment but also reduces frequent maintenance and replacement.

Ground shock-absorbing bricks are suitable for various projects and buildings, such as underground garages, subway stations, airports, highways, stage performances, etc. In these scenarios, earthquakes and noise are common problems and ground shock-absorbing bricks can play an important role. Not only can it provide better protection for engineering projects and the surrounding environment, but it can also reduce the frequency of engineering repairs and reduce maintenance costs.

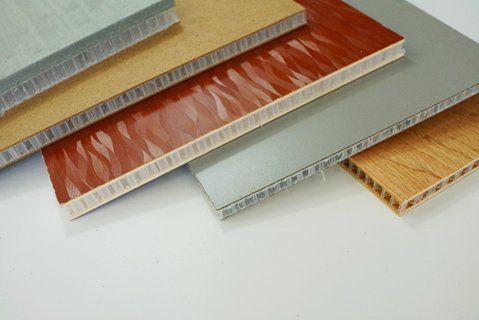

4. Honeycomb sound insulation panel/ honeycomb sound absorption board:

Honeycomb acoustic panels are made up of a series of small cells arranged in parallel, separated by narrow gaps, creating a multi-reflective echo. When sound waves propagate to the surface of the sound insulation board, they first come into contact with the honeycomb surface and then are repeatedly refracted in the honeycomb gaps until they are dissipated or absorbed. It is an ideal indoor sound insulation material.

Its raw material is 100% polypropylene, which has the characteristics of sound-absorbing, environmentally friendly, flame retardant (impregnated with flame retardant), heat insulation, moisture-proof, mildew-proof, easy to remove dust, easy to cut, easy to construct, good stability, and good impact resistance. With the advantages of high-cost performance, the honeycomb core can be compounded with different surface materials, such as HPL boards, PVC surface materials, FRP boards, etc. Each surface material has a wide variety of colors to choose from, which can meet different styles and levels of sound absorption. Decoration needs.

Not all sound frequencies can be blocked by honeycomb soundproofing panels. Objects have inherent resonant frequencies. For sounds that are close to the resonant frequency of the object, the soundproofing effect of the soundproofing board will be reduced.

The non-woven plastic honeycomb core produced by our company can be compounded with many surface materials. It can be compounded with PVC to make ceilings, compounded with wood to make wall panels and floors, and compounded with stone to make lightweight kitchen countertops. No matter what surface material is combined with it, the board can be given the function of sound insulation and noise reduction. Ideal for home decoration as well as cabinet panels for lightweight boat hulls, car bodies and interior furniture. In addition to the surface material, its customizable items can also be customized in the size, thickness and hole diameter of the honeycomb core. For more product information, please browse our product list or leave us a message.