Which one is better? Support plate structure or Support strip structure?

Two types of stone are used in custom cabinets: granite and quartz. Quartz stone is relatively complex, wear-resistant and low-cost. The physical properties of the countertop are stable, durable and easy to care for. Therefore, the general cabinet countertops use quartz stone as the surface material and add different materials underneath it to support the plate.

The traditional wooden support boards/strips are not strong and easily corroded by moisture, their structures will deform over time. Therefore, it is necessary to install other support boards or strips of materials between the quartz stone panels and cabinets to prevent the countertop from deforming due to the sinking of the cabinet and to prevent the countertop from being broken due to uneven stress.

How does plastic honeycomb solve this problem?

As wooden structures gradually withdraw from the kitchen home decoration market. Nowadays, metal or plastic honeycomb laminate panels are commonly used to make countertops. The structure is generally divided into support strips and support plates it is a strip pad or a support plate, the purpose is to make the force on the table more uniform, reduce the chance of cracking, and increase the stability of use.

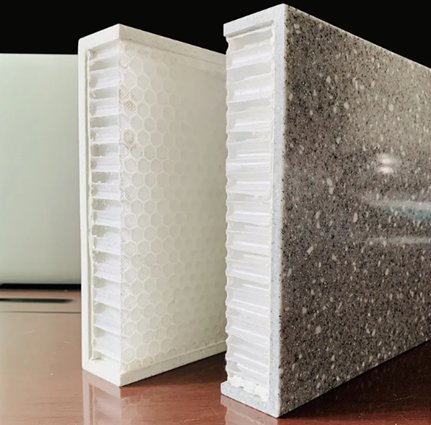

LEFT: Plastic honeycomb support panel RIGHT: Plastic support strip

What are the characteristics and advantages of the two structures?

Support strip

The strips are distributed according to points. Generally, 3 or 4 strips are placed under the surface plate, and other positions are empty. The more pads are added, the cost will increase accordingly. But it does not mean that the more you add, the more stable it will be. In fact, the basic 3 rods are enough. 3-point distribution, cost-effective, safe and reliable.

Plastic honeycomb support panel

Nowadays, the support panel of the Countertop will generally use polypropylene honeycomb as the main material, The honeycomb structure of polypropylene material not only increases its load-bearing capacity to protect the countertop, at the same time reduces the weight and has the function of noise reduction. The current rock slabs mainly use plastic honeycomb plates as support plates. Because the rock slab is hard and very thin, the probability of being cracked or broken by impact during processing, transportation, or use is very high. After the honeycomb composite, this accident will be greatly reduced, and it has been unanimously praised by practitioners.

What can we supply?

Achieving PP honeycomb panels use imported polypropylene raw materials, which are lightweight, high strength, waterproof, moisture-proof, and mildew-proof. The internal honeycomb structure can buffer and absorb shock, can protect the countertop better, silence and reduce noise, and extend the service life of the countertop.

The surface non-woven fabric will reduce the construction difficulty of kitchen countertop manufacturers and thus reduce costs; as a factory, our company has the ability to produce large quantities in a short time; Located in the port city of Qingdao, we can also further save your logistics and transportation costs.