Current motorbike helmets, designed for the severity of head injuries or to avoid the occurrence of injuries, are the only protective system for the head. In recent decades, a major focus in helmet design has been the optimization of the helmet material properties to ensure the best protection for the head, for a given impact energy level or impact speed.

Although in the past decades, both the shell and liner material properties and geometry have been optimized to offer high levels of protection, more work is needed to overcome the difficulty in increasing the energy absorption provided by current helmets.

A way to improve the energy absorption characteristics of current helmets is to use non-traditional materials with higher energy absorption capacity while keeping the acceleration transmitted to the head at safe levels.

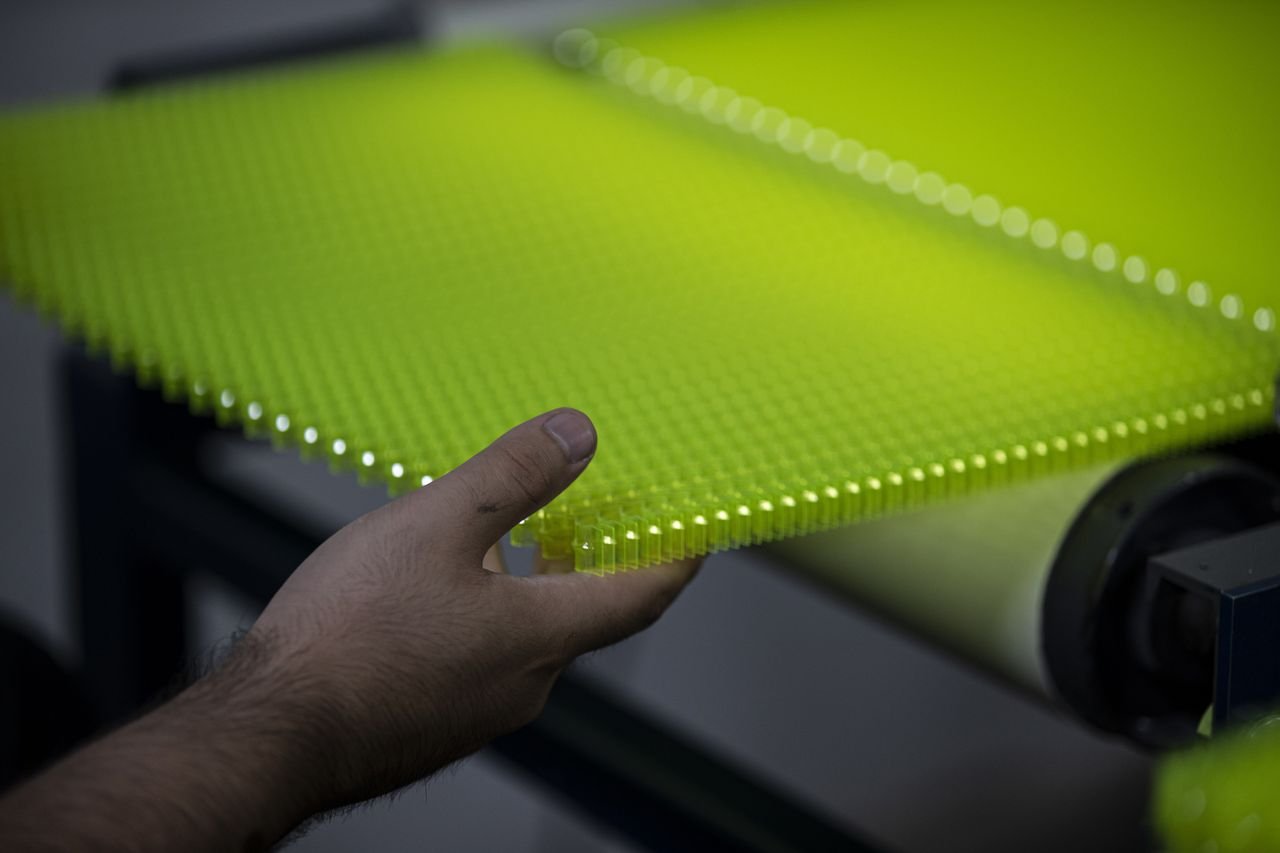

Introducing a honeycomb core structure into the lining of innovative helmets as a solution can enhance the shock absorption performance of motorcycle helmets. At the same time, the honeycomb structure can effectively absorb noise, reduce the impact of external noise on drivers, and improve attention during safe driving. The plastic honeycomb helmet had excellent seismic resistance and noise reduction performance, thereby improving the protection function of the driver's head. We recommend researcher use the Polycarbonate honeycomb as the test material due to its great shock absorb performance.

Achieving Honeycomb Panel is now inviting motorcycle helmet manufacturers worldwide to cooperate with us to protect bikers on the road, we will provide the free samples for you. Our self-development of the honeycomb production line can greatly improve the honeycomb core production efficiency and provide high quality honeycomb core for our customers.