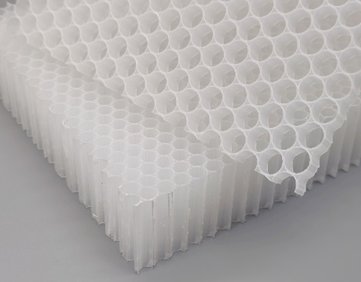

Low density: Since the honeycomb is a porous discontinuous material, and the cross-sectional area of the solid part is very small, the density of the honeycomb is also very small, so the overall mass is light, meeting the lightweight requirements in aerospace design.

Good sound insulation and heat insulation properties: in commonly used honeycomb sandwich panels, the volume of solid materials is 1%-3%, and the remaining space is air in a sealed state. Since the sound insulation and heat insulation properties of air are better than any solid material, the propagation of heat and sound waves is greatly restricted, so the honeycomb sandwich panel has good sound insulation and heat insulation properties.

Strong shock-absorbing performance: Because the honeycomb panel has many dense honeycombs that restrain each other, like many small I-beams, it can disperse and bear the pressure from all aspects, thus playing a shock-absorbing effect.

Superior flatness and rigidity: superior to the vertical stress of the honeycomb core, and each honeycomb panel has countless fixed honeycombs and will not move. The dense honeycombs that restrain each other in the honeycomb panel can disperse and withstand pressure from all aspects, making the panel evenly stressed, ensuring its strength to withstand pressure and ensuring high flatness when the panel has a larger area.

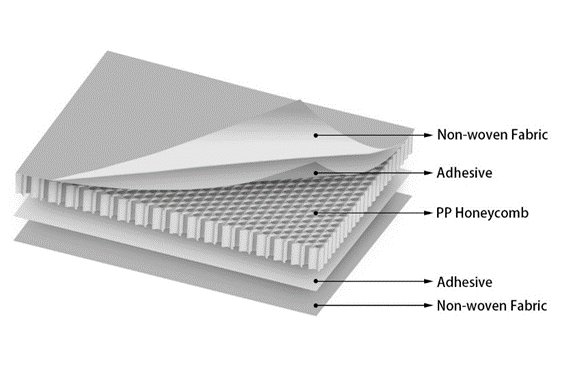

For the modern furniture industry, which has strict environmental protection requirements, using honeycomb panels as furniture processing materials is a good material choice in the new century. Its complete green quality allows furniture manufacturers to avoid many things when processing furniture. Necessary environmental protection procedures: honeycomb panel panels can be diversified, such as solid wood, aluminium board, gypsum board, and natural marble, and the material selection is easy. The PP honeycomb core can be laminated with a layer of non-woven fabric on both sides and can be laminated with a variety of panels.