Product description

◆ PP honeycomb core panel is made of Polypropylene, and the surface tissue is carbon fiber.

◆ Standard cell size is 8mm diameter, also have 6mm/10mm for choice.

◆ Common density is 80kg/m3, min is 60, max 100 kg/m3.

◆ PP honeycomb core panel is made of Polypropylene, and the surface tissue is carbon fiber.

◆ Standard cell size is 8mm diameter, also have 6mm/10mm for choice.

◆ Common density is 80kg/m3, min is 60, max 100 kg/m3.

| Specific | width by length | width by length | width by length |

| PP8T40 | 1220*2440 | 1150*2300 | 1500*3000 |

| PP10T40 | 1220*2440 | 1150*2300 | 1500*3000 |

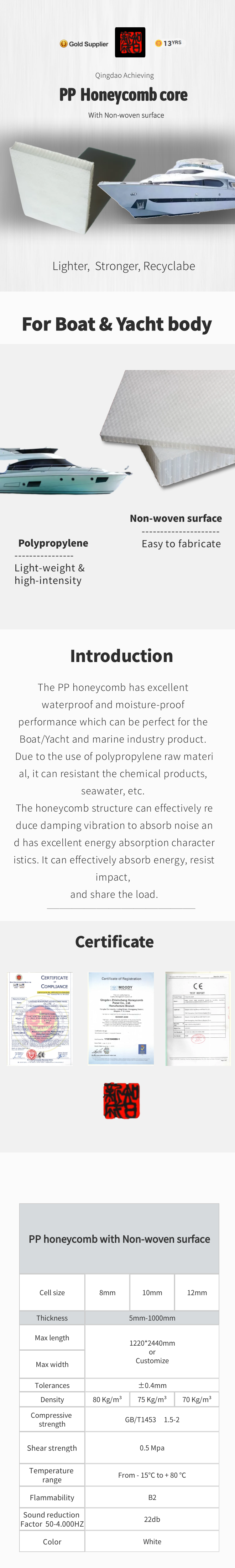

Introduction

Qingdao Achieving PP honeycomb core are made from high-quality Polypropylene raw material. And we laminated different surface material layers in order to make the honeycomb sandwich panel reach more function and possibly for more purpose in different usage scenarios. In construction and architecture, sandwich honeycomb panel is employed for lightweight cladding panels, partitions, false ceilings, and furniture. Its strength-to-weight ratio makes it suitable for applications where weight reduction is desired without compromising strength and rigidity. The automotive industry utilizes sandwich honeycomb panel for lightweight panels and structures in vehicle interiors, such as door panels, headliners, trunk liners, and parcel shelves. It helps to reduce weight while maintaining structural integrity and sound insulation.

For surface material, we provide different options such as PC, Acrylic, Marble, quartz, Fiberglass, CFRT, PVC, ABS, Wood, Veneer, Wood pattern paint-free surfaces, antislip etc. Thinner plastic sheet surface can and wooden pattern.

PP honeycomb sandwich board, the PP honeycomb core and hard light stronger, higher rigidity, waterproof, and eco-friendly. lightweight, insulation, sound reducing, waterproof, increase rigidity, easy install. Its resistance to water and moisture, combined with its lightweight nature,

Specification

Standard size is 1200*2400mm

Standard cell sizes are 8mm/6mm/10mm.

Standard density is 80kg/m³, which also provides 60m³ or 90 kg/m³.

Standard thickness 15mm/20mm/25mm/30mm or customize.

Required different MOQ based on different surface materials, please leave a message for more info.

Application

Polypropylene honeycomb sandwich panels can be used to make interior components, air ducts and insulation and sound insulation components for a variety of automotive OEMs. Black polypropylene composite/sandwich board can also be used as a suitcase floor. In addition to automobile parts, the honeycomb sandwich panels can also be used for cargo car bodies, ship interiors, swimming pools and furniture.

Marble, ceramic tiles, quartz board, granite or other stone bounded with PP honeycomb core for countertop or kitchen tabletop. Polypropylene honeycomb core, as a backing panel/baseboard/bottom plate. Due to its hollow honeycomb core, it has the properties of sound insulation, moisture resistance, heat insulation, and cold resistance. the anti-bending and shear strength is significantly improved, greatly reducing the breaking rate during transportation, installation, and use, making it more convenient for installation and transportation, and reducing energy consumption and costs. More importantly, it can be used as a decorative stone ceiling.

Fibreglass (FRP/GRP) honeycomb sandwich panel is suitable for dry containers, container houses and truck boxes.

For larger sizes, we offer a steel frame reinforced inside. The floor with aluminium antislip surface is also available, it provides a higher impact resistance surface, waterproof, rust-proof and anti-slip pattern.

CFRT(Continuous fibre reinforced thermoplastic) composites, as a new type of thermoplastic composite material with high strength, high rigidity, high toughness, and recyclability, have made outstanding contributions to the lightweight of automobiles. Meanwhile, CFRT honeycomb panels can also be used in fields such as photovoltaic power generation, high-speed rail, aviation, and high-pressure oil pipelines.

FRP/CFRT can be used for truck floors, RV floors, van floors, stage boards and so on after composite with non-slip surfaces. Its ultra-lightweight property not only achieves load-bearing strength as a floor but also facilitates transportation and disassembly. The honeycomb structure of good mechanical properties, so the carriage plate/floor/plate/support plate has good toughness, impact resistance, high compressive strength, shock buffering, high stiffness, good bending performance and other excellent mechanical properties.

Our FRP honeycomb sandwich panel /plate/board are widely used for refrigerated trucks, van/truck body, container house floor, swimming pool, water entertainment park building, small pier etc.

As wall panels, plastic honeycomb panels can provide superior acoustic performance as they effectively absorb mid-frequency and higher-range sounds. Compared with traditional wall panels, polypropylene composite board has significant strength and is 60% lighter than plywood wall panels. The huge weight difference makes honeycomb panels easier to transport and more cost-effective.

composite honeycomb board drywall decora wall coat, lightweight, insulation and waterproof.

PP(polypropylene) honeycomb panels are much lighter than solid particle boards while still offering the same load capacity. This means that furniture made from PP(polypropylene) honeycomb panels can be easier to transport and assemble, resulting in lower labour costs.

The Achieving Laminates honeycomb sandwich panel is a honeycomb structure furniture panel with a smooth surface that's easy to clean, which makes the furniture weight much lighter and easier to install. The honeycomb sandwich panel is moisture-proof, waterproof, easy to maintain, less weight, and easy to DIY install which makes it a good choice for furniture boards, load-bearing plates, table surfaces, even panels of small-size boxes walls etc.

If you have any questions or needs about the product, please fill in the following form and we will contact you as soon as possible.